Shaping Electrical Power to Ensure Energy Efficiency

Shaping Electrical Power to Ensure Energy Efficiency

Solutions

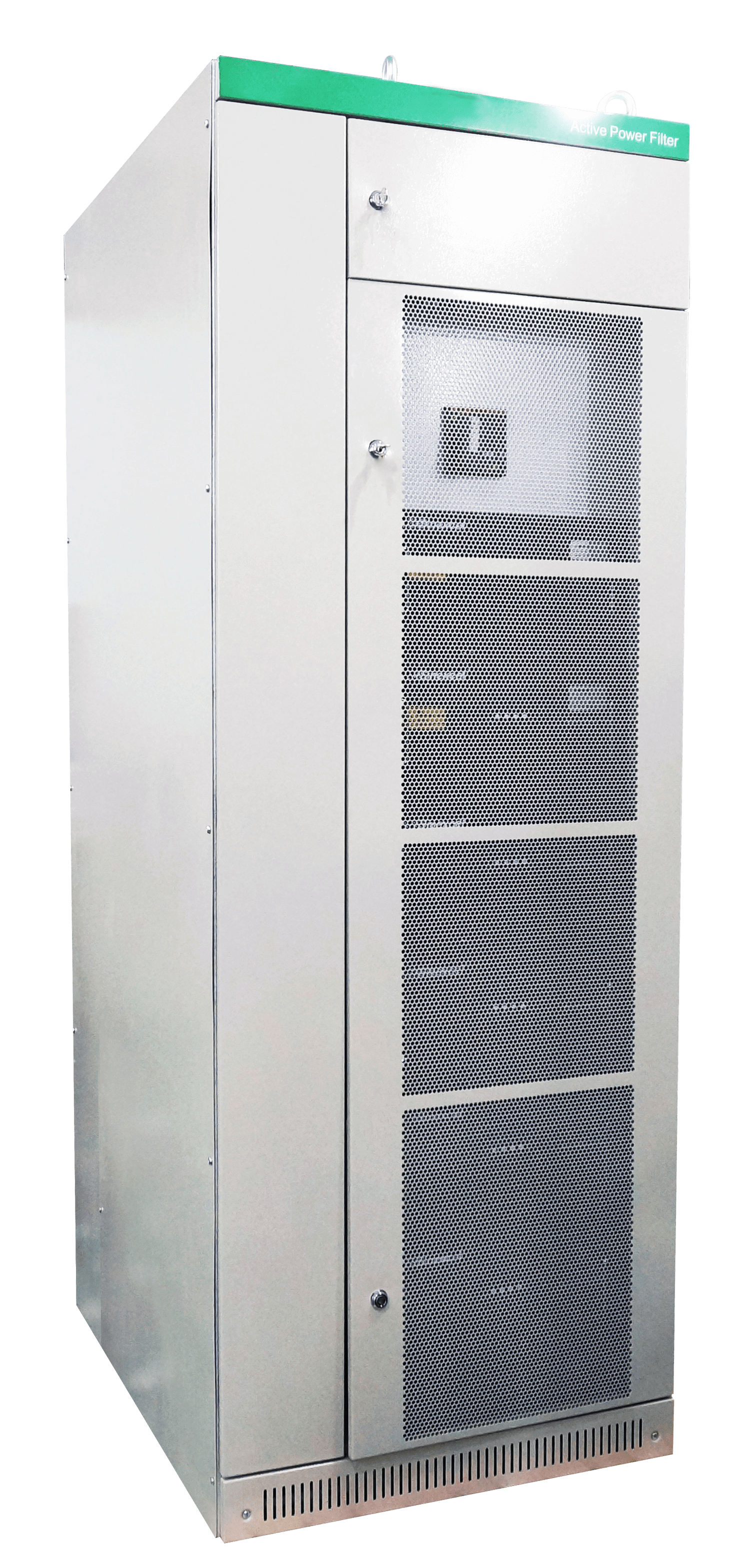

Harmonic Mitigation/Filtration

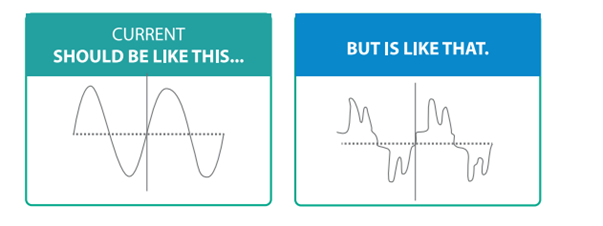

Harmonics in an electric power system are a result of non-linear electric loads such as Variable speed drives, UPS, Furnaces & lighting . Harmonic frequencies in the network are frequent cause of power quality problems.

Impact of Harmonics

- Overload of cables, components , capacitors, transformers causes additional losses, decrease of lifetime, increased maintenance costs.

- The current distortion (THDi) through the system impedance can generate voltage distortion (THDu) which can cause malfunction or failure of many types of equipment being supplied from the same power line.

- Excessive currents in the neutral conductor.

- Nuisance tripping of Circuit Breakers.

- Lowering power factor, increase of reactive power consumption.

Sufferers

Power consumers, network operators , power industry

Solution

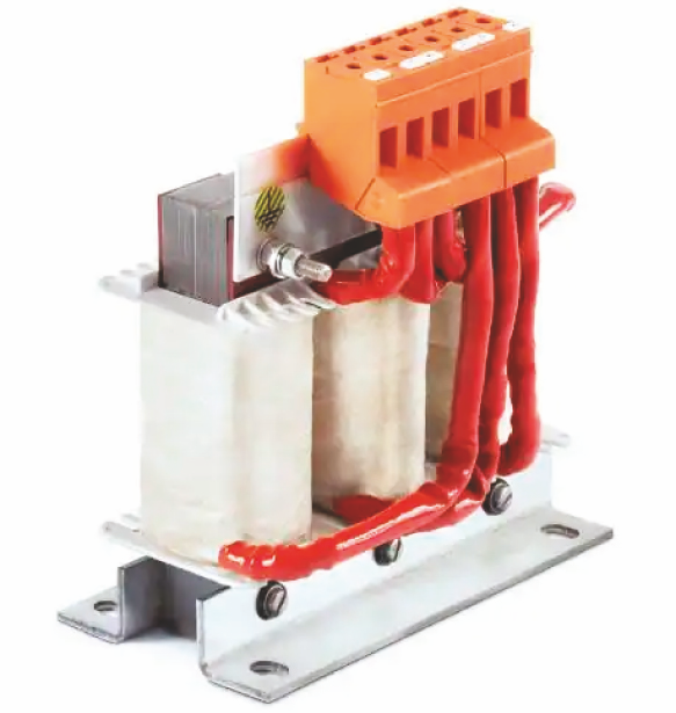

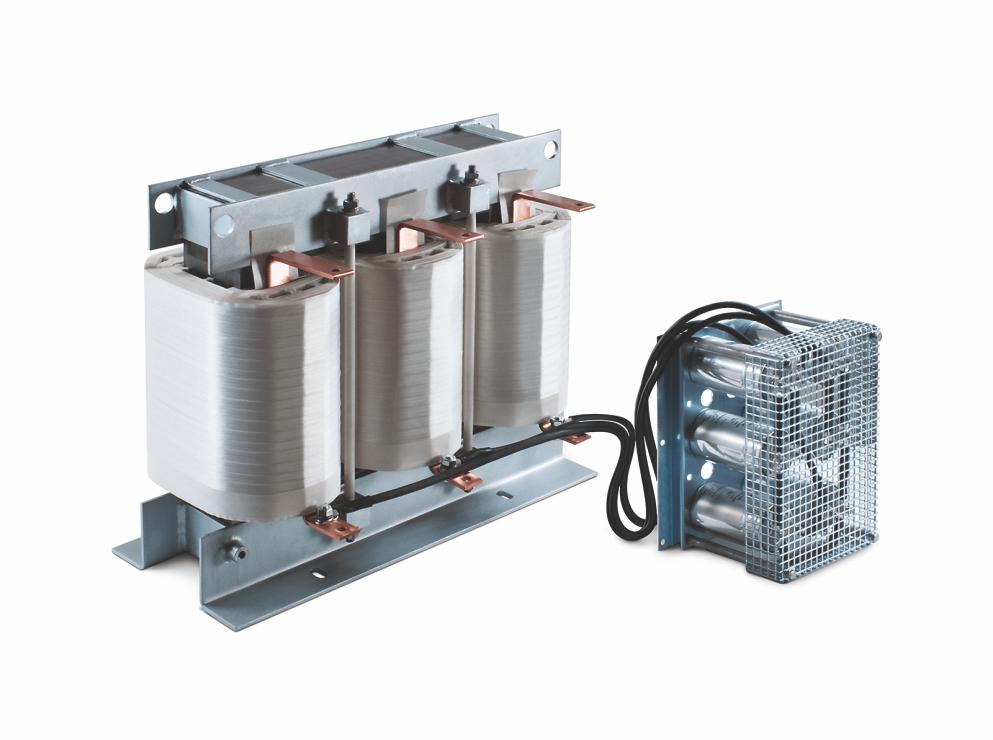

Harmonics can be Filtered through a combination of reactors and capacitors (Passive Filters) or by injecting exact opposite of the harmonics detected through active Filter into the network.

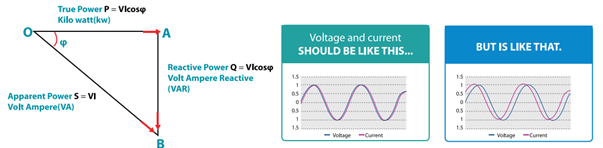

Power Factor Correction

Equipment's connected in network like transformers, motors, capacitors etc causes phase angle difference between current and voltage. When the current is phase-shifted from voltage , it takes more current to deliver the same amount of active power (KW). This more current drawn causes increase in apparent power (KVA).

Impact of Low Power factor

Economic Impact

Low PF causes utility to increase its generation and transmission capacity in order to handle extra demands caused by increased KVA. This will lead to unnecessary high amount of payment in electricity bill due to high reactive power in system. You pay for apparent power but use active power (higher electricity bill). Some Power Distribution boards deploy penalty on lower Power factor than the specified level defined.

System Impact

Reduces transformer capacity due to high reactive power in system. Rise or drop in voltage level due to excess lead or lag reactive power in system can reduce system load eciency such as disturbances in motor torque due to voltage irregular variation.

Sufferers

All Industrial , commercial & Infra Power consumers, network operators , power industry

Solution

Power factor of a facility can be improved by installing capacitor banks , Invertor based PF correction Equipment's & Hybrid PF correction Systems.

Benefits of increased Power Factor

Reduction in cost of energy and reduced consumption due to increased efficiency of system. Better voltage profile, reduced power loss and release of system capacity.

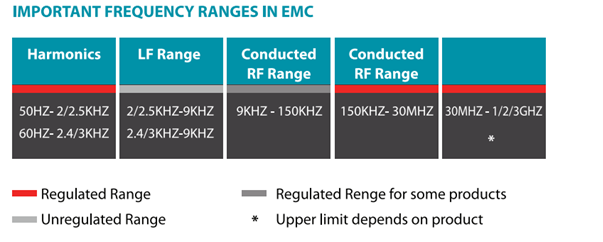

Electromagnetic Interference ( EMI) suppression

EMI/EMC lters & components are devices that directly counter the eects of interference to stabilize the electrical ow of signal transmission, thus ensure the safe and reliable operation of electrical and electronic equipment.

Location of Deployment

In the mains Power Supply line , Usually immediately next to the Source of Interference.

Importance of EMI Filtration

It ensure that electronic products do not interfere with other devices or systems and they can function correctly in their electromagnetic environment.

It ensure safety of the end users. Products that do not comply with EMC regulations may risk human health and safety that leads to accidents or malfunctions.

Compliance with EMC regulations is also essential to avoid penalties, fines and even legal action. In addition, if a product is found to be non-compliant, it may be withdrawn from the market leading to significant financial losses for the manufacturer.

Motor Protection

VFD output side peripherals for motor protection

An electrical panel is a metal box with main circuit breaker in the electrical panel that regulates the electricity to the entire distribution feeders across the network . These feeders with circuit breakers are designed to automatically shut off when there is too much electrical current flowing through them. Offering advanced protection, fault protection and seamless integration with energy management and control systems improves the performance of Electrical Panel . Electrical panel clearance is important for energy efficiency because it allows your panel to operate at its optimal temperature and avoid overheating , thus proper clearance inside the panel is important for fire prevention because it reduces the risk of ignition and spread of flames. This measure helps in improving life span of the panel.

Areas of concern at Motor drive output

Excessive dv/dt , Peak and overvoltage , Parasitic earth currents , Eddy current losses in the motor , Bearing currents , Acoustic motor noise

Solutions

dv/dt reactors (increase inductivity, signal smoothing)

dv/dt filters (low inductance & Capacitance, facilitates

In controlling the voltage peaks to sustainable level)

Sinusoidal output filters (High L and C for optimizing the output signal by converting it to Sine Wave)

Good and Valuable Reasons by using output Filters

Protect the motor against voltage peaks hence prolongs the lifetime Reduces the losses in the motor

- Lower copper and iron losses, -Less heat inside the motor

Eliminates acoustic switching noise from the motor

Reduces semiconductor losses in the drive with long motor cable

Possible longer motor cable with proper Voltage Regulation

Voltage Conditioning

Voltage Regulation Solutions help control fluctuating voltages or power supply that could otherwise be detrimental to electrical machinery. Disturbances such as power sags and surges affect sensitive electronics devices found in Industrial Machinery ,vehicles, computers, and battery charging systems to name a few. There are several types of power disturbances that lead to unsafe and sometimes expensive electrical malfunctions. However, the proper voltage regulation technology can help control both sags and surges in voltage, protecting your electrical device. Besides this there are other areas which cause Power variation and Power outage because of which the operation of entire plant or facility goes to stand still.

POWER SURGE

A power surge occurs when high voltage electrical loads shut down in short inter- vals or when electricity is sent back into the system.

Solution

Surge Suppressor

Power SAG

A sag, or dip, is a short interval reduction in low voltage on ac power systems, and is more common than surges. A sag in power supply occurs when electric motors start-up, ground faults, and power systems are undersized.

Solution

Voltage conditioners

Power variation and Power outage

Back up Power

Solution

UPS / Low voltage Regulators.

DG Synchronisation

Diesel Generator synchronization is the process of matching technical electrical parameters such as voltage, frequency, phase angle, phase sequence of Diesel Generator with a healthy or running power system. This is required to be done just before the generator is reconnected to the power system DG Synchronization Panel is controlled by PLC to control DG ON/OFF operation based on load condition.

For Example 4Nos of 1500KVA DG are available in Operation Condition. When load is 1000KVA, only one 1500KVA (DG1) will be in operation. When load increased above 1200KVA that is 80% of 1500KVA, PLC will give command to other 1500KVA DG's i.e. DG2, DG3 & DG4 to operate. In these way all 4DGs will be controlled.

Electrical Panel Performance & Life enhancement

An electrical panel is a metal box with main circuit breaker in the electrical panel that regulates the electricity to the entire distribution feeders across the network . These feeders with circuit breakers are designed to automatically shut off when there is too much electrical current flowing through them.

Offering advanced protection, fault protection and seamless integration with energy management and control systems improves the performance of Electrical Panel . Electrical panel clearance is important for energy efficiency because it allows your panel to operate at its optimal temperature and avoid overheating , thus proper clearance inside the panel is important for fire prevention because it reduces the risk of ignition and spread of flames. This measure helps in improving life span of the panel.